Maximum

performance

Our high-performance

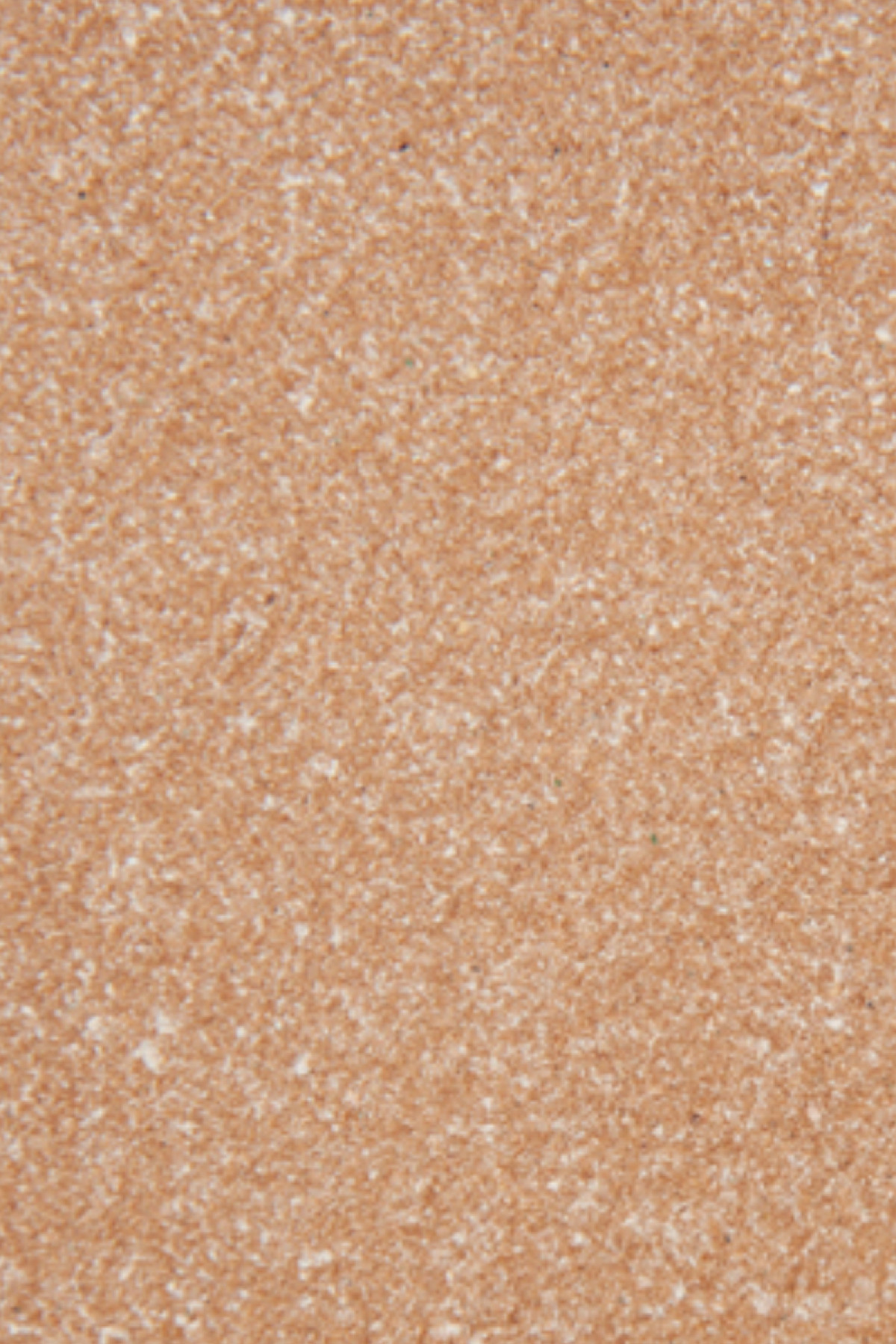

quality leather fibre material and consists of almost 100% natural, renewable raw materials and forms the basis for your product worlds.

Our production process is similar to that of paper. Specific formulations are mechanically crushed from leather sections from leather processing companies, and vegetable tanning agents natural rubber, natural fats and water are added, all according to customer requirements.

Our production process is similar to that of paper. Specific formulations are mechanically crushed from leather sections from leather processing companies, and vegetable tanning agents natural rubber, natural fats and water are added, all according to customer requirements. At the end of this sophisticated manufacturing process, we obtain a customised, sustainable leather fibre fabric in large rolls or sheets (from 25/50 m), based on the individual formulation. Depending on further customer requirements, the material can be ground, smoothed, dyed and processed further. The configuration of the selected processing steps depends on your surface requirements & other product properties. With Top_Cover we produce unique, customised surface finishes and therefore modularisable material solutions in varying thicknesses from 0.3 to 7 mm.

People have been enjoying the benefits of leather for the past 600,000 years. The sensory qualities of this material are firmly anchored in our cultural and sensory DNA. That’s why leather and its use in objects appeals so wholly to our sense of vision, touch and smell. The core concept of sustainable material cycles rounds off the positive emotional impact of our products.